SIMATIC Real-Time Location System

The positioning foundation for Digital Enterprises.

SIMATIC RTLS (Real-Time Location System) is an indoor positioning solution developed by Siemens, one of the leading companies in the field of industrial automation. SIMATIC RTLS utilizes real-time location technology to track and manage the positions of devices, workers, and assets within a manufacturing environment.

Now that it is growing, the need to control equipment and people in production plants is increasing. To meet that need, Siemens offers a wireless management solution in the factory with many outstanding advantages:

The SIMATIC RTLS solution provides the following tools and features:

-

Real-time positioning: SIMATIC RTLS enables real-time positioning of objects within the factory with high accuracy and fast update rates. The system utilizes technologies such as RFID (Radio Frequency Identification), Ultra-Wideband (UWB), and Wi-Fi to determine precise locations and continuously update data

-

Location and movement management: SIMATIC RTLS provides tools for managing the location and movement of devices and assets within the factory. Users can track and control the positions of devices, goods, or workers in real-time, while receiving notifications and alerts for any unauthorized or exceptional movement

-

Factory operations optimization: SIMATIC RTLS provides crucial information about the location and status of devices and assets within the factory. By monitoring and analyzing this data, managers can optimize the arrangement and operation of production processes, thereby improving efficiency and increasing factory productivity.

-

Enhanced workforce safety: SIMATIC RTLS provides the ability to track the location of workers within the factory, ensuring their safety and preventing workplace accidents. In the event of a hazardous situation, the system can emit warning signals and assist in quickly locating personnel in need of rescue.

-

Asset management optimization: SIMATIC RTLS enables the management and tracking of the location of important assets such as machinery, equipment, and materials within the factory. This helps minimize search time and increase asset utilization, while also preventing loss and waste.

A product is tracked position during production.

In some countries, the Corona virus is on a positive downward trend, but factories still limit personnel and must adhere to a safe distance between individuals. Thanks to the RTLS locator solution, individuals will be updated with their location or alerted to other employees about a distance violation. This is monitored and recorded to ensure that all employees' activities are observed and the risk of spread is well controlled in the context of the Covid-19 epidemic still in some parts of the world.

Once the factory is equipped with RTLS technology, this is also the beginning stage for the digitization of production lines. The pallets, packages will be tracked from the time of the finished product to the storage and delivery stage, all controlled by transponders. Helps locate packages accurately and quickly, reducing time spent searching for goods, spare parts and supplies in the warehouse. Contributing to increasing the efficiency of the factory's production process control.

Control the device assembly process with the navigation system

The SIMATIC RTLS (Real-Time Location System) consists of the following components:

-

Readers: Readers are sensor devices placed in strategic locations within the factory or industrial area to collect data about the location of tracked objects. Readers typically utilize technologies such as RFID (Radio Frequency Identification), Ultra-Wideband (UWB), or Wi-Fi to gather information from tags or positioning devices.

-

Tags: Tags are small devices attached to the objects that need to be tracked, including mobile devices, machinery, assets, or workers. These positioning tags often contain sensors and transmit signals regarding their location to the readers.

-

Data Storage System: The Data Storage System is used to store and manage information about the location of tracked objects. This system handles the storage and organization of data related to the current location and movement history of the objects.

-

Management Software: The Management Software is used to display and manage information about the location of objects within the RTLS system. It provides a user interface that allows for tracking and controlling object positions, creating alerts and reports, and optimizing production operations.

-

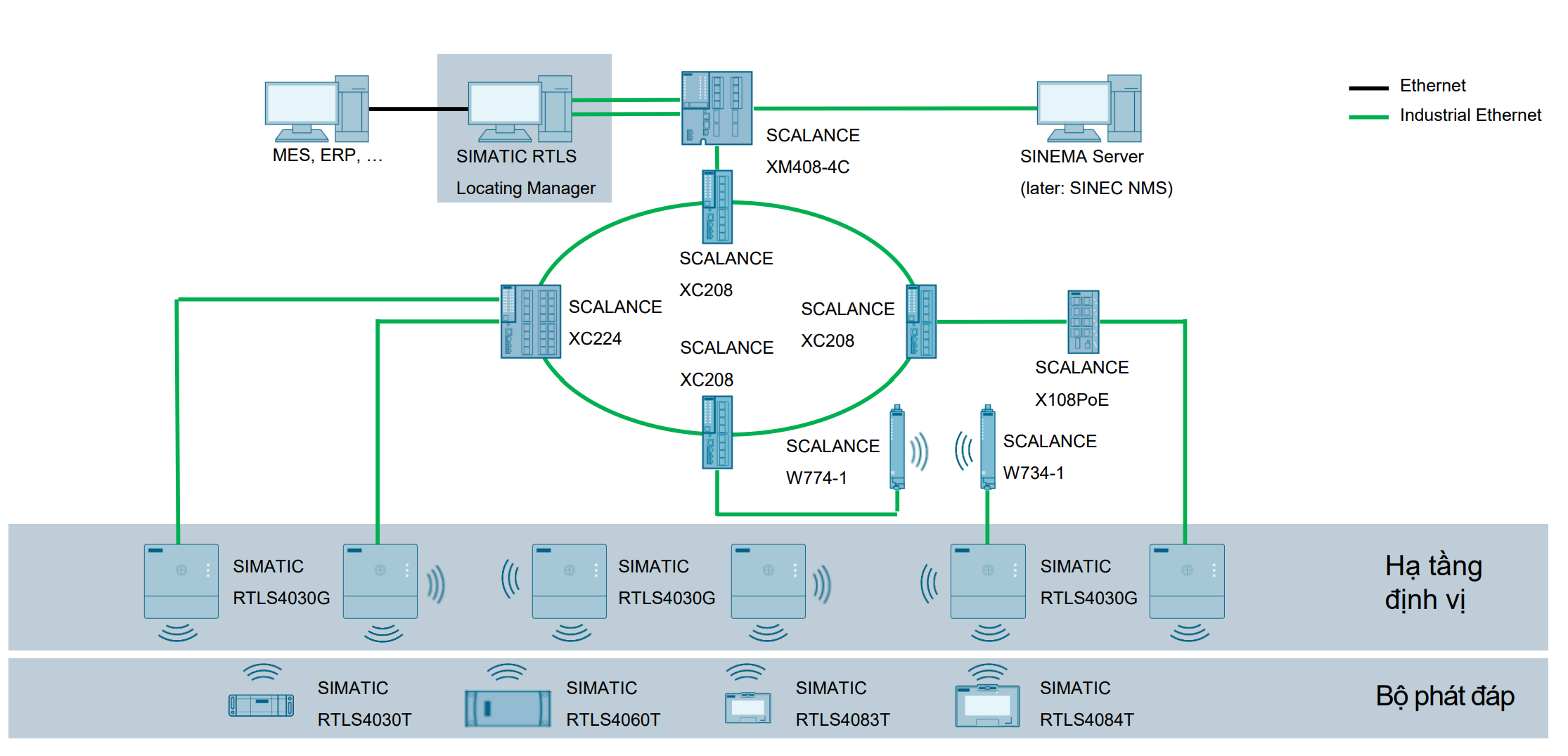

Network Infrastructure: The Network Infrastructure provides connectivity between readers, tags, and the data storage system. It ensures the accurate and fast transmission of location data throughout the entire system.

-

ChatGPT User Interface: The User Interface allows managers and end-users to access and interact with the system. It provides features such as location tracking, alert configuration, report generation, and data management.

The operating principle of the system is as follows:

Hardware connections are made up of devices such as Anchors, Gateways, which play the role of transmitting signals and receiving information from Transponders and devices mounted directly on the object to be monitored called Transponders. Depending on the needs of each system, the connection and arrangement of Gateway and Anchor are appropriate. In other words, there are two communication layers in the system. The class of mobile devices is equipped with Transponder, the devices in this class can move according to the pre-programmed control (Mobile Production Equipment), the other layer is a real-time location and acquisition system. Signals from the Transponders will be collected by fixed Anchors on a high position above the ground, then will transmit the signal to the Gateways, the tasks of the Gateways will now be synthesized and sent to the routing software. Location at the monitoring room, with positioning software and data analysis from the Gateway, parameters such as the location of the device will be updated and transmitted quickly and accurately.

Moreover, if instead of sequentially transmitting data from Transponder to Anchor and then to Gateways, now Gateways can also take on the role of an Anchor and transmit directly to the calculation software, then data can be transmitted to the enterprise's management system such as ERP,.... A special thing about the system is the use of wireless communication, which allows us to limit the connection and easily change So, repair. Currently, we have been implementing RTLS model for a number of factories in many fields such as food, paper, etc.

Through this, we can see the importance of RTLS in the innovation of production processes and system digitization. Any waste of time for the search and lookup processes will be solved if there is an intervention of the RTLS system. Provide users with a new reliable, flexible, and advanced system. Contributing to promoting the digitization of businesses in the country in particular and around the world in general.

For more information please contact us:

THIEN TAN ENGINEERING TECHNOLOGY CO., LTD

🏠 Headquarters: 1685/37 Le Van Luong, Hamlet 3, Nhon Duc Commune, Nha Be District, Ho Chi Minh City

🏠 Representative office address: DP12, Dragon Parc Villa, Phu Long Residential Area, Nguyen Huu Tho Street, Phuoc Kien Commune, Nha Be District, HCMC

📞 Phone: 028 3636 7192 📠 FAX: 028 3636 7092

🏘 Hotline: 0985 715 585

📧 Email: info@thientanetc.com